Comparison of Stress Distribution of Wave One and Reciproc Instruments Using a Finite Element Analysis

Ugur Inan1*, Neslihan B Keskin2, Ozgur Keskin1

Affiliation

- 1Department of Endodontics, Faculty of Dentistry, 19 Mayis University, Samsun, Turkey

- 2Balgat Oral Health Center, Ankara, Turkey

Corresponding Author

Dr. Ugur INAN, 19 Mayis University, Faculty of Dentistry, Department of Endodontics, 55139 Kurupelit, Samsun, Turkey, Tel: +90 362 3121919/ 3287 (office); Fax: +90 362 457 60 32; E-mail: ugurinan29@hotmail.com

Citation

Inan, U., et al. Comparison of Stress Distribution of WaveOne and Reciproc Instruments Using a Finite Element Analysis. (2016) J Dent & Oral Care 2(1): 1-4.

Copy rights

©2016 Inan, U. This is an Open access article distributed under the terms of Creative Commons Attribution 4.0 International License.

Keywords

Finite element analysis; Fracture; Nickel-titanium

Abstract

Objective: The aim of this study was to compare and evaluate the stress distribution of two different reciprocating systems (Reciproc R25 and WaveOne Primary) with different cross-sectional geometries under bending or torsional conditions using a finite element model.

Materials and Methods: Size # 25.08 of two different NiTi instruments was selected for the study. 3-D finite element models were constructed for each file and mechanical behavior of these files were compared under bending (1 N and 2 mm) and torsional (2.5 Nmm and 10°) conditions.

Results: Under 1 N bending load, both instruments showed similar mechanical behavior. When a 2 mm deflection applied, Reciproc R25 was more flexible. Torsional tests revealed that WaveOne had lower stress concentrations at 10° rotation. When the angle of rotation increased, Reciproc R25 had lower stress concentration.

Conclusion: WaveOne Primary showed comparable flexibility to Reciproc R25 under high bending loads and low torsional forces.

Introduction

One of the major innovations in endodontics has been the use of nickel titanium (NiTi) alloy for manufacturing rotary instruments[1]. Using NiTi rotary instruments have substantially reduced the incidence of complications, but despite the increased flexibility and strength of the alloy, NiTi rotary instruments still have a higher risk of fracture[2].

To improve the fatigue resistance, flexibility and cutting efficiency of rotary NiTi files, manufacturers tried to alter the endodontic instrument designs by surface engineering (implantation or electropolishing) or heat treatment[3]. In 2007, a new NiTi wire (M-Wire) was produced by a thermomechanical processing procedure and showed better resistance to cyclic fatigue[4].

The use of reciprocating motion with a single file was proposed by Yared (2008) with the advantages of eliminating prion cross-contamination and reduction of instrument fatigue[5]. In 2011, two systems operating with reciprocating motion were introduced into the market as Reciproc (VDW, Munich, Germany) and WaveOne (Dentsply Maillefer, Ballaigues, Switzerland). The use of reciprocating motion was shown to increase the fracture resistance of NiTi instruments in a number of studies[6-10].

It has been suggested that the design of an instrument is an important factor in their torsional or bending behaviors, as it affects the stress distribution and stress concentration on the files[11-13]. As a result of this, manufacturers have introduced different designs for NiTi rotary instruments, claiming to have a lower tendency to fracture.

Finite Element Analysis (FEA) is a numerical method that can calculate stress distributions and stress concentrations for prescribed geometry, material properties, and loading conditions[11,12]. The purpose of this study was to compare and evaluate the stress distribution of two different reciprocating NiTi instruments with different cross-sectional designs under bending or torsional conditions using a FEA model. The null hypothesis tested was that no difference was present in the stress distribution of different reciprocating NiTi instruments with different cross-sections tested.

Materials and Methods

Two as-received rotary NiTi files operating with reciprocating motion were selected for this study. Reciproc R25 with an S-shaped cross-section was compared with WaveOne Primary which had a modified convex triangular design.

Three dimensional FEA was carried out as described by previous studies[11-14]. FEA models of the instruments were constructed by expressing all boundary conditions and geometric configuration numerically. The modeling of cross-sectional configurations was accomplished by serial grinding of an embedded instrument and capturing the shape with an image-measuring device integrated microscope (DM2500 Leica Microsystems GmbH, Wetzlar, Germany). Then an idealized shape was established in CAD software (SolidWorks; Dassault Systemes, Velizy- illacoublay, France). As the handle of the file does not have any function in the shaping procedure, it was neglected in the numerical analysis. Finally, a mesh of non-linear, eight-noded, hexahedral elements was overlaid onto the rendered 3D image. There were 20492 elements with 23872 nodes for Reciproc, and 10032 elements with 12811 nodes for WaveOne in this 3D model. This numerical model both instruments was entered into a 3D FEA package (ABAQUS V6.13-1; SIMULIA, Providence, RI, USA) with the z-axis running along the length of the instrument. A nonlinear, stress–strain behavior of the NiTi material was entered for the NiTi material during the mathematical analysis[15].

Mechanical behaviors of the instruments were analyzed numerically as described by Kim el al.[16] in a previous study. Briefly, a load of 1 N was applied at the tip of the file, while its shaft was stabled and the von Mises stress distribution was evaluated. Then, under the similar condition, the tip of the file was deflected 2 mm and the von Mises stress distribution was examined.

In the second part of the experiment, torsional behavior was evaluated by applying a 2.5 Nmm force to the shaft in a clockwise direction normal to the long axis of the instrument, as the 4 mm of the tip was rigidly constrained. Also a 10° clockwise rotation was applied to the instrument under the same condition and the von Mises stress distribution was evaluated.

Results

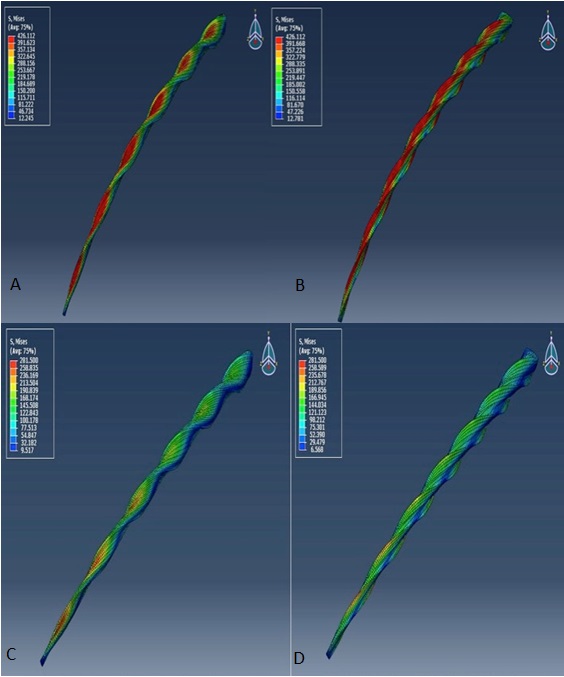

Under 1N bending load, the calculated stress on WaveOne and Reciproc instruments were both found 426 MPa. A color scale was used to represent the stress values from minimum (blue) to maximum (red). According to this color scale, the maximum stress was located in the flutes for both instruments (Fig 1A and Fig 1B).

Under a 2 mm deflection, the von Mises stresses were 281 MPa for WaveOne and 259 MPa for Reciproc. The maximum stress was located in the flutes for Reciproc and on the cutting edges for WaveOne according to the color scale (Fig 1C and Fig 1D).

Figure 1: Stress distributions under 1 N bending load: A. Reciproc R25. B. WaveOne Primary; and 2 mm deflection. C. Reciproc R25. D. Waveone Primary

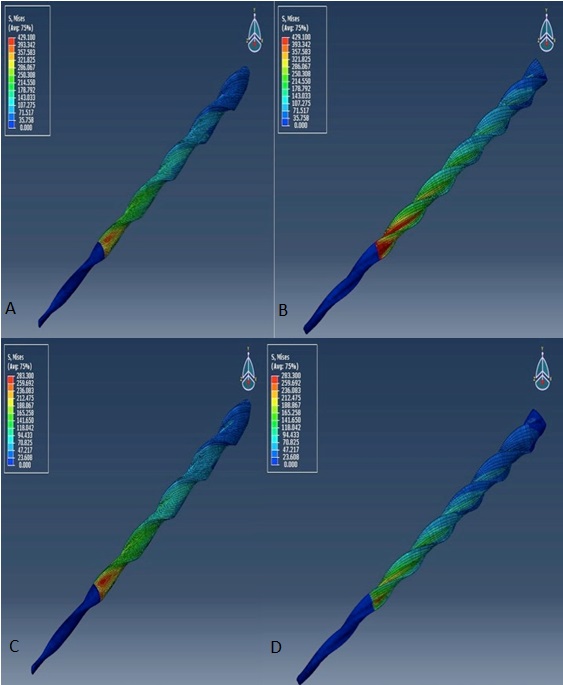

The distribution of von Mises stress under 2.5 Nmm torsional load was 429 MPa for WaveOne and 383 MPa for Reciproc. The maximum stress occurred at the base of the flutes near the fixed 4 mm apical part of the instrument for WaveOne. The numerical analysis also showed that Reciproc had 13.53° rotation and WaveOne had 24.75° rotation at 2.5 Nmm torque. When a 10° clockwise rotation was applied, the von Mises stresses were 266 MPa for WaveOne and 283 MPa for Reciproc (Fig 2A-D).

Figure 2: Stress distributions under 2.5 Nmm torsional load: A. Reciproc R25. B. WaveOne Primary; and 10° rotation. C. Reciproc R25. D. Waveone Primary

Discussion

In the last decade, the popularity of rotary NiTi instruments has increased and a number of systems were introduced to the market[16]. However, the main clinical problem with the use of rotary NiTi instruments is fracture which can occur without any visible signs of previous permanent deformation[17,18]. It has been well-documented that the fracture of instruments used in rotary motion occurs torsional[17], flexural[19] or in combination of the two[20].

Two reciprocating files (Reciproc R25 and WaveOne Primary) were selected for this investigation. As the stress fracture in rotary endodontic instruments results from continuous repetitive loading[6], special clockwise and counter-clockwise movements of the reciprocating instruments has the advantage of relieving stress on the instrument. As a result of this, NiTi instrument lifespan extends in comparison with continuous rotation[6,10,21].

In the present study, we compared bending or torsional conditions of Reciproc R25 and WaveOne Primary reciprocating files using a FEA. Under 1 N bending load, similar stress distributions were observed for the two rotary files. However, under 2 mm bending load, Reciproc had lower stress values than WaveOne. This might be due to the reason that stress depends not only on the applied forces but also on instrument cross-section[12,13] In a previous study, Arbab-Chirani et al[22] compared 5 rotary NiTi instruments with different cross sections and found that ProTaper instrument (triangular design) was stiffer than Mtwo (S-shaped) instrument under a 3.8 mm bending force. Also ProTaper instrument showed a greater level of torque at 22° angle. Kim et al[12] compared 4 rotary NiTi instruments with different cross sections using FEA and S-shaped Mtwo system was found most flexible according to a displacement-curve analysis. However, the authors also stated that stiffness curves were non-linear, especially for M two system which has a similar design with Reciproc used in the present study.

Under 2 mm bending deflection, higher von Mises stress values were observed for WaveOne than Reciproc instruments. The reason of this condition might be that higher bending forces might occurr on the stiffer instruments. It was also reported that the instruments with triangular cross-section were stiffer than S-shaped instruments and would develop greater level of bending effort[22]. As the S-shaped Reciproc is more flexible than the triangular shaped WaveOne, stress concentration was lower for Reciproc instrument. However, under a 1 N bending load, Reciproc and WaveOne instruments showed the same stress values. The reason of this might be that the more flexible Reciproc bent more than WaveOne instrument, showing more deformation and stress.

In the torsion tests, a constant torque of 2.5 Nmm and rotation of 10° were applied on the instruments. Under 2.5 Nmm, torque, WaveOne showed higher stress values than did the Reciproc, while at 10° rotation Reciproc showed higher stress values. As the cross section geometry affects the stiffness values of an instrument with the same length and taper[12], when lower forces applied, WaveOne instrument with triangular cross-section (larger inner core) had lower stress values. However, under higher torsional stresses, WaveOne experienced higher von Mises stresses. In a study comparing 5 different NiTi instruments, ProTaper instruments (triangular) experienced maximum stress under 22° rotation, while Mtwo (S-shaped) had the lowest[22]. It should be noted that resistance to torsional forces would increase as the inner core area of an instrument cross-section increases[11].

FEA is a method to evaluate mechanical behavior of the instruments such as stress distribution[23]. FEA is useful to evaluate the stress and strain distribution on the instruments which is very difficult by in vitro tests[24]. There are a number of studies which compared several NiTi instrument systems especially with different cross-sections[12,22,25-27]. However, in these studies, evaluation methods were quite different. For example, while Arbab-Chirani et al[22] applied a 3.8 mm bending load and 22° torsional load; Montalvao et al[14] used 1 N bending load and 2 mm bending displacement. The authors also applied 2.5 Nmm and 10° torsional loads. Berutti et al[26], applied 2.5 Nmm to evaluate torsional behavior and 2.9 Nmm to evaluate the behavior at bending. In another study, to compare the torsional stiffness of rotary NiTi instruments with 4 different cross-sections, Baek et al[27] applied a 20° torsinal load. As a result of this, it can be concluded that it is not an easy task to compare the results of these studies with varying bending or torsional loads applied.

Conclusion

According to the results of the present study, Reciproc R25 was more flexible than WaveOne Primary under 2 mm deflection. When the bending force increased to 1 N, both rotary NiTi instruments showed similar mechanical behaviors. Under 10° rotation, triangular based WaveOne exhibited lower stress, however, under higher rotations S-shaped Reciproc showed lower stress values.

References

- 1. Testarelli, L., Plotino, G., Al-Sudani, D., et al. Bending properties of a new nickel-titanium alloy with a lower percent by weight of nickel. (2011) J Endod 37(9): 1293-1295.

- 2. Parashos, P., Messer, H.H. Rotary NiTi instrument fracture and its consequences. (2006) J Endod 32(11): 1031-1043.

- 3. Gutmann, J.L., Gao, Y. Alteration in the inherent metallic and surface properties of nickel-titanium root canal instruments to enhance performance, durability and safety: a focused review. (2012) Int Endod J 45(2): 113-128.

- 4. Shen, Y., Zhou, H., Zheng, Y.f., et al. Current challenges and concepts of the thermomechanical treatment of nickel-titanium instruments. (2013) J Endod 39(2): 163-172.

- 5. Yared, G. Canal preparation using only one Ni-Ti rotary instrument: preliminary observations. (2008) Int Endod J 41(4): 339-344.

- 6. De-Deus, G., Moreira, E.J., Lopes, H.P., et al. Extended cyclic fatigue life of F2 ProTaper instruments used in reciprocating movement. (2010) Int Endod J 43(12): 1063-1068.

- 7. Pedulla, E., Grande, N.M., Plotino, G., et al. Influence of continuous or reciprocating motion on cyclic fatigue resistance of 4 different nickel-titanium rotary instruments. (2013) J Endod 39(2): 258-261.

- 8. Pérez-Higueras, J.J., Arias, A., de la Macorra, J.C. Cyclic fatigue resistance of K3, K3XF, and twisted file nickel-titanium files under continuous rotation or reciprocating motion. (2013) J Endod 39(12): 1585-1588.

- 9. Kiefner, P., Ban, M., De-Deus, G. Is the reciprocating movement per se able to improve the cyclic fatigue resistance of instruments? (2014) Int Endod J 47(5): 430-436.

- 10. Plotino, G., Grande, N.M., Porciani, P.F. Deformation and fracture incidence of Reciproc instruments: a clinical evaluation. (2015) Int Endod J 48(2): 199-205.

- 11. Xu, X., Eng, M., Zheng, Y., et al. Comparative study of torsional and bending properties for six models of nickel-titanium root canal instruments with different cross-sections. (2006) J Endod 32(4): 372-375.

- 12. Kim, H.C., Kim, H.J., Lee, C.J., et al. Mechanical response of nickel-titanium instruments with different cross-sectional designs during shaping of simulated curved canals. (2009) Int Endod J 42(7): 593-602.

- 13. Zhang, E.W., Cheung, G.S., Zheng, Y.F. Influence of cross-sectional design and dimension on mechanical behavior of nickel-titanium instruments under torsion and bending: a numerical analysis. (2010) J Endod 36(8): 1394-1398.

- 14. Montalvao, D., Alçada, F.S. Numeric comparison of the static mechanical behavior between Profile GT and Profile GT Series X rotary nickel-titanium files. (2011) J Endod 37(8): 1158-1161.

- 15. Wang, G.Z. A finite element analysis of evolution of stress–strain and martensite transformation in front of a notch in shape memory alloy NiTi. (2007) Mater Sci Eng A Struct Mater 460: 383-391.

- 16. Kim, T.O., Cheung, G.S., Lee, J.M., et al. Stress distribution of three NiTi rotary files under bending and torsional conditions using a mathematic analysis. (2009) Int Endod J 42(1): 14-21.

- 17. Sattapan, B., Nervo, G.J., Palamara, J.E., et al. Defects in rotary nickel-titanium files after clinical use. (2000) J Endod 26(3): 161-165.

- 18. Cheung, G.S., Peng, B., Bian, Z., et al. Defects in ProTaper S1 instruments after clinical use: fractographic examination. (2005) Int Endod J 38(11): 802-809.

- 19. Pruett, J.P., Clement, D.J., Carnes, D.L. Cyclic fatigue testing of nickel-titanium endodontic instruments. (1997) J Endod 23(2): 77-85.

- 20. Wei, X., Ling, J., Jiang, J., et al. Modes of failure of ProTaper nickel-titanium rotary instruments after clinical use. (2007) J Endod 33(3): 276-279.

- 21. De-Deus, G., Leal Vieira, V.T., Nogueira da Silva, E.J., et al. Bending resistance and dynamic and static cyclic fatigue life of Reciproc and WaveOne Large instruments. (2014) J Endod 40(4): 575-579.

- 22. Arbab-Chirani, R., Chevalier, V., Arbab-Chirani, S., et al. Comparative analysis and bending behavior through finite-element models of 5 Ni-Ti endodontic instruments. (2011) Oral Surg Oral Med Oral Pathol Oral Radiol Endod 111: 115-121.

- 23. Montalvao, D., Shengwen, Q., Freitas, M. A study on the influence of Ni-Ti M-Wire in the flexural fatigue life of endodontic rotary files by using Finite Element Analysis. (2014) Mater Sci Eng C Mater Biol Appl 40: 172-179.

- 24. Gao, Y., Cheung, G.S., Shen, Y., et al. Mechanical behavior of ProTaper universal F2 finishing file under various curvature conditions: a finite element analysis study. (2011) J Endod 37(10): 1446-1450.

- 25. Turpin, Y.L., Chagneau, F., Vulcain, J.M. Impact of two theoretical cross-sections on torsional and bending stresses of nickel-titanium root canal instrument models. (2000) J Endod 26(7): 414-417.

- 26. Berutti, E., Chiandussi, G., Gaviglio, I., et al. Comparative analysis of torsional and bending stresses in two mathematical models of nickel-titanium rotary instruments: ProTaper versus ProFile. (2003) J Endod 29(1): 15-19.

- 27. Baek, S.H., Lee, C.J., Versluis, A., et al. Comparison of torsional stiffness of nickel-titanium rotary files with different geometric characteristics. (2011) J Endod 37(9): 1283-1286.