Effect of Baobab (Adansonia Digitata) Fruit Inclusion on Lipid Composition, Mineral Analysis, Physicochemical and Sensory Properties of Ice Cream

ABUBAKAR ALHAJI LIMAN

Affiliation

1Department of Food Technology, Federal College of Freshwater Fisheries technology New Bussa, Niger State, Nigeria

2Department of Food Technology, Federal University, Dutsimma, Katsina State, Nigeria

Citation

Liman. A., et al. Effect of Baobab (Adansonia Digitata) Fruit Inclusion on Lipid Composition, Mineral Analysis, Physicochemical and Sensory Properties of Ice Cream. (2017) Int J Food Nutr Sci 4(2): 128- 133.

Copy rights

© 2017 Liman. K. This is an Open access article distributed under the terms of Creative Commons Attribution 4.0 International License.

Abstract

Ice cream is not considered an ideal dessert as it contains high quantities of milk and cream fats which can have adverse effects on human health. Hence, most research effort has been focused on producing highly palatable and yet nutritious low fat ice cream. Over the years, attempt has also been made to find cheaper substitutes for cream due to its rising cost, scarcity and civilization diseases associated with its consumption. In this study photochemical rich ice cream products were strategically developed by incorporating baobab fruit pulp in the formulation. Twenty panellists evaluated the sensory properties of the products while lipid composition, mineral and physicochemical analyses were carried out in accordance with standard methods and procedures. The range of the sensory scores among the ice cream samples are; colour (6.05 - 8.60), taste (6.70 - 8.50), consistency (6.50 - 8.20), flavour (7.40 - 8.50) and overall acceptability (7.40 - 8.50). Results showed significant decrease in the scores of the entire sensory attribute tested with the inclusion level of baobab fruit pulp above 20%. The overrun, titratable acidity, total solid, melting point, milk solid not fat and water activity of the control and baobab fruit formulated ice creams were also investigated. There were no significant differences at P < 0.05 between the plain and among baobab formulated ice cream in total solid, melting point, water activity and milk solid not fat. However, the overrun and titratable acidity of the baobab formulated ice cream samples were significantly higher than that of plain ice cream. The ice creams investigated had in them the range of fatty acids as: lauric acid (0.20 - 0.30)%, myristic acid (0.30 - 1.20)%, palmitic acid (18 - 25)%, palmitoleic acid(4 - 12)%, oleic acid (40 - 47)%, linoleic acid (10 - 18)%, linolenic acid (1.00 - 5.00)%, arachidic acid (1.00 - 2.00)% and arachidonic acid (0.50 - 2.00)%.The result revealed a significant different (P < 0.05) among the ice cream samples in the composition of all the fatty acids found except lauric acid. The total cholesterol of the ice cream significantly decreases as the inclusion levels of baobab fruit pulp increases. The macro-minerals investigated comprised of sodium, potassium, calcium, magnesium, iron and phosphorus while the micro-minerals studied are zinc, manganese, copper and selenium. All the minerals except copper and manganese were found significantly (P < 0.05) higher in baobab incorporated ice creams. Ice cream producers can now adopt this strategic method to produce a more nutritious and healthier ice cream with higher overrun and melting resistant.

Introduction

Consumption of junk foods has increased manifold, which has led to a number of health problems (increased risk of cardiovascular diseases, diabetes, cancer, high fracture risk instead of other wise and so on). Nowadays, the consumers trends has been towards foods with more natural antioxidants, dietary fibres, natural colorants, minerals, vitamins, low calories, low cholesterol and low fat and free of synthetic additive[1]. Ice cream is one of the most popular foods worldwide and highly appreciated by a very broad spectrum of consumers. Ice cream even though is considered as food of higher nutritional and caloric density, it is poor in dietary fibre and some of the natural plant base antioxidants. Some consumers are also sceptical about its consumption due to health consciousness; keeping away from saturated fat, cholesterol and lactose intolerance. Hippocrates considered by some to be the father of western medicine was reported to have said around 2000 years ago, ‘let thy food be thy medicine and medicine be thy food[2]. Edible wild fruits are known to have nutraceutical properties and they can be used to fortify stapple foods particularly for malnourished children[3]. Baobab (Adansonia digitata L)[4] is a wild tree which has a long history of use in Africa. Its fruit pulp is traditionally consumed in Africa by children, expectant mothers and senior citizens as food and to fight off illnesses[4]. one hundred gram of baobab pulp, provides up to 300mg of vitamin C (ascorbic acid) which is six fold higher than that contained in orange[5], 293 - 300 mg of calcium (twice the calcium in milk), 231 mg of potassium that is about six times higher than in banana and 0.2 - 0.6 mg of sodium[6] 2.16 - 3.19 mg of beta-carotene[7] , 121.5 mg of total polyphenol, 111.73 mg of total flavonoid and 106.68 mg total proanthocyanin[8] and 96 - 118 mg of phosphorus[9,10]. Baobab fruit also has a cream-like colour and thus can be a suitable vehicle for the fortification in the production of dairy products. In spite of all these nutraceutic potentials to solve the problems of malnutrition and to prevent and treat diseases, it is underutilized in Nigeria. Therefore keeping in view the increasing demand of ice cream and increased consumer awareness about healthy eating habits, this research was designed to develop photochemical rich ice cream incorporating baobab fruit pulp at varying levels and to evaluate the lipid composition, mineral analysis as well as physicochemical and sensory properties of the products. It envisaged that this strategy will tremendously make the ice cream more nutraceutic.

Materials and Methods

Materials

The baobab fruits were collected from the wild around Bukka Village in Mokwa Local Government Area of Niger State. Milk, egg, gelatine, vanilla, sugar and ice cream powder were procured from Monday market in New Bussa Niger State while borehole water, sensitive weighing balance and measuring cylinder and pasteurizer were obtained from Food Technology Department of Federal College of Freshwater Fisheries Technology New Bussa, Niger State, Nigeria. The cream powder was purchased from Safara foods in New Bussa, Niger State, Nigeria.

Processing of fine powdered fruit: The baobab fruit has a hard shell (epicarp) with a velvety covering, inside the shell is the seed per carp and seed which are hard and dark coloured and surrounded by dry light/ cream coloured fruit pulp (monocarp) forming lumps. Dry slightly darker fibrous material is also contained within the fruit and the pulp (mesocarp) is what is consumed traditionally. The fruit collected from the trees in the wild, their hard shells were cracked and the pulp was separated from the seeds and the shells. This was milled using hammer-mill and sieved using mechanical shaker. The fine powder collected was packed inside air-tight containers.

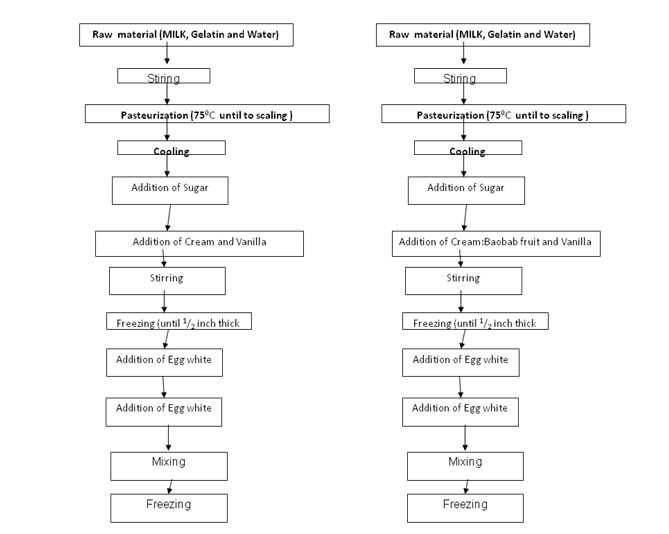

Ice cream formulation: Ice cream samples were produced with the incorporation of baobab fruit pulp at 0% (sample A), 20% (sample B), 40% (sample C) and 60% (sample D) concentration with cream, whole milk powder, sugar, egg, gelatine, vanilla and water accurately measured as shown in table 1 and following the steps described in figures 1 and 2 below

Figure 1: Flow Chart of Ice Cream Production.

Figure 2: Flow Chart of Baobab-Ice Cream Production.

Physicochemical analysis: The analysis of samples for water activity, titratable acidity, total solid, over-run, Milk Solid Not Fat (MSNF) and melting point were carried out at Central Laboratory of National Institute for Freshwater Fisheries Research, New Bussa, and Niger State, Nigeria. Milk solid not fat, melting point and water would be determined in accordance with AOAC. 1990[11].

Total titratable acidity: The titratable acidity was calculated as percentage of lactic acid by titration with 0.1N NaOH in accordance with the method of AOAC, 2000[12].

Determination of total solids content

Total solids content was determined according to the modified method of AOAC[13]. Two grams of ice cream sample was placed in a clean dried flat bottom aluminium dish. The dishes were heated on a steam bath for 10 - 15 minutes and then transferred to an air oven for 12 hours at 50°C. The dishes were placed into desiccators to cool and then weighed. Heating, cooling and weighting were repeated several times until the difference between two successive weights is less than 0.5 mg. The total solids content was calculated as follows:

(weight of sample after drying)

Total solids (%) = ------------------------------------------- × 100

(weight of sample before drying)

Table 1: Ingredients formulation.

| MATERIALS (g) | SAMPLE | |||

|---|---|---|---|---|

| A | B | C | D | |

| Milk | 23 | 23 | 23 | 23 |

| Cream | 15 | 12 | 9 | 6 |

| Sugar | 20 | 20 | 20 | 20 |

| Egg | 8 | 8 | 8 | 8 |

| Gelatin | 1 | 1 | 1 | 1 |

| Vainlla | 1 | 1 | 1 | 1 |

| Baobab | 0 | 3 | 6 | 9 |

| Water | 82 | 82 | 82 | 82 |

| Total | 150 | 150 | 150 | 150 |

Overrun determination

Overrun measurement was made by using a known volume of ice cream mix and frozen ice cream to determine both the weight of ice cream. It was then calculated based on weight using a formula described by Arbuckle[14].

Mineral analysis

K and Na were analyzed with flame photometer, P, Ca Zn, Se, Cu, Mg, Fe and Mn were analysed using Atomic Absorption Spectrophotometer. Each mineral was determined at appropriate wavelength with their respective lamps[12]

Fatty acid determination of ice creams (AOAC, 2005)

Typically involve extraction of the fat from its source, hydrolysis to Fatty acids, methylation to Fatty Acid Methyl Esters (FAMEs) and quantification using Gas Chromatography with Flame Ionization Detector. Specifically, 5 g of ice cream sample was weighed with pyrogallic acid into a Mojonnier flask to which an internal standard, ethanol and 8.3 M HCl were added. The sample was hydrolyzed at 70 – 80oC using water bath and cooled at room temperature with addition of ethanol and ether and proper shaking. The mixture was centrifuged and the Ether layer decanted. After evaporating the water, the residue was dissolved in chloroform. The extracted fatty acid was then methylated by addition of boron fluoride (7% BF3) with toluene, and then sealed in vials and used in Gas Chromatography – Mass Spectroscopy (GCMS) determination. GCMS was at 60°C for 5 mins in the oven and finally at 10°C/min to 280°C (held for 10 min) using analytical column 100 m x 0.25 mm ID, 0.2 um, flow rate of 0.7 mL/Min.

Cholesterol determination in ice creams (Acetic ferric Chloride reagent method): AOAC, 2005; Hesham et al, 2015[13].

Standard cholesterol of 1 mg/ml was prepared in chloroform. The standard was placed in tubes which contained 0.1 ml of the test sample. To this, 1 ml of chloroform was added. Three millilitres of acetic acid and 3 ml of acetic ferric chloride reagent were added. The mixture was left in the dark for 30mins and the absorbance read at 560 nm. A blank test was also prepared which serve as the control.

Choleterol(mg/ml) = (Absorbance of sample) / (Absorbance of standard cholesterol) × Concentration of standard cholesterol

Sensory evaluation

Sensory evaluation was carried out after 3 days of the production of the ice cream. The ice cream samples were coded and 20 panellists comprised of students from Department of Food Technology, Federal College of Freshwater Fisheries Technology New Bussa, Niger State, Nigeria were requested to evaluate the samples base on the quality attributes such as colour, taste, texture or consistency, flavour and overall acceptability. The scores would be based on nine point hedonic scale with the descriptive terms ranging from 9 = like extremely to 1 = dislike extremely.

Statistical analysis

The data were statistically analyzed using Statistical Package for Social Sciences (SPSS) version 20.0. Analysis Of Variance (ANOVA) was used to compare the mean for significant differences. Post-hoc Duncan’s Multiple Range Tests was used for separation of mean. Differences were accepted as significant at P < 0.05.

Discussion

Sensory Properties of plain and Baobab incorporated ice creams

Mean scores of colour, taste, texture, flavour and overall acceptability of the ice cream samples are presented in Table 2. The range of the sensory scores among the ice cream samples are; colour (6.05 - 8.60), taste (6.70 - 8.50), consistency (6.50 - 8.20), flavour (7.40 - 8.50) and overall acceptability (7.40 - 8.50). Results showed significant decrease in the scores of the entire sensory attribute tested with the inclusion level of baobab fruit pulp above 20%. The participants liked and accepted the control sample better than ice cream samples with baobab fruit incorporated. This study conformed to similar findings which reported that replacement of dairy fat with tapioca dextrin or potato malt dextrin significantly affects textural[15] and flavour[16] properties of ice cream.

Table 2: Sensory score of Ice Creams.

| Sample | A | B | C | D |

|---|---|---|---|---|

| Colour | 8.60a | 7.80ab | 7.00b | 6.05c |

| Taste | 8.50a | 7.95ab | 7.35b | 6.70c |

| Consistency | 8.20a | 7.90ab | 7.35b | 6.50c |

| Flavour | 8.50a | 8.15a | 7.35b | 7.40b |

| Overall acceptability | 8.50a | 8.20a | 7.30b | 7.40b |

Mean in the same row with different superscript are significantly different (P < 0.05)

Table 3: Fatty Acid Content of plain and baobab fruit pulp incorporated Ice Creams.

| Fatty acids (%) | Samples | |||

|---|---|---|---|---|

| A | B | C | D | |

| C12 : 0 | 0.20a | 0.30a | 0.30a | - |

| C14 : 0 | 1.20a | 0.50b | 0.30c | 0.30c |

| C16 : 0 | 25.00a | 22.00b | 20.00c | 18.00d |

| C16 : 1 | 4.00c | 5.00c | 10.00b | 12.00a |

| C18 : 1 | 45.00b | 47.00a | 45.00b | 40.00c |

| C18 : 2 | 10.00c | 15.00b | 15.00b | 18.80a |

| C18 : 3 | 5.00 a | 2.00b | 1.00b | 5.00a |

| C20 : 0 | 2.00a | 2.00a | 1.00ab | - |

| C20 : 1 | 0.50b | - | 1.00ab | 2.00a |

Mean in the same row with different superscripts are significantly different (P < 0.05)

Table 4; Percentage Total Fatty acids and Total Cholesterol of plain and baobab fruit pulp incorporated ice creams.

| Parameters | Samples | |||

|---|---|---|---|---|

| A | B | C | D | |

| Saturated fatty acid (SFA) | 28.40a | 24.80a | 21.60a | 18.30a |

| Monounsaturated fatty acid (MFA) | 49.50a | 52.00a | 56.00a | 54.00a |

| Polyunsaturated fatty acid (PFA) | 7.00c | 17.00b | 16.00b | 23.80a |

| Cholesterol (mg/g) | 4.50 ± 0.16a | 4.30 ± 0.70b | 4.08 ± 1.05c | 3.81 ± 0.18d |

Table 5: Mineral Contents of Ice Cream samples.

| Minerals (mg/g) | Samples | |||

|---|---|---|---|---|

| A | B | C | D | |

| Na | 1.55 ± 0.14c | 1.75 ± 0.21b | 1.75 ± 0.14b | 1.86 ± 0.12a |

| K | 1.70 ± 0.2d | 1.88± 0.50c | 2.04± 0.17b | 2.77± 0.20a |

| Ca | 3.08± 0.42d | 3.60± 0.33c | 3.69± 0.30b | 3.80± 0.01a |

| Mg | 1.89± 0.26d | 2.06± 0.35c | 2.20± 0.60b | 2.31± 0.50a |

| Fe | 0.30± 0.10c | 0.34± 0.12b | 0.35± 0.20b | 0.40± 0.10a |

| P | 3.06±1.30c | 3.16± 0.70b | 3.17± 0.98b | 3.50± 0.22a |

| Zn | 0.10± 0.02d | 0.15± 0.11c | 0.20± 0.10b | 0.30± 0.01a |

| Mn | 0.03± 0.01a | 0.04± 0.01a | 0.04± 0.01a | 0.02± 0.01a |

| Cu | 0.01± 0.00a | 0.01± 0.00a | 0.01± 0.00a | 0.01± 0.00a |

| Se | 0.29± 0.13b | 0.30± 0.60ab | 0.30± 0.12ab | 0.32± 0.10a |

Mean + Standard deviation with different superscript letters in a row differ significantly (p < 0.05).

TABLE 6: Physical and chemical properties of ice cream made with varying levels of baobab fruit pulp.

| Parameters | Samples | |||

|---|---|---|---|---|

| A | B | C | D | |

| Total solid (%) | 43.09+ 1.50a | 43.81+ 0.58a | 44.49+ 0.89a | 44.31+1.28a |

| Titratable Acidity (%) | 0.19+ 0.00b | 0.20+ 0.00b | 0.22+ 0.00a | 0.22+ 0.00a |

| Melting point (°C) | 27.00+ 2.83b | 28.50+ 3.51b | 30.50+ 2.12a | 31.00+ 2.83a |

| MSNF % | 12.29 + 1.07a | 15.12+ 1.07a | 14.00+ 1.05a | 13.42+ 1.07a |

| Water activity (%) | 55.69+ 1.29a | 56.92+ 1.49a | 55.51 +0.89a | 56.19+ 0.58a |

| Overrun (%) | 49.23+ 1.29b | 49.79 + 0.30b | 52.37+ 0.04a | 53.05+0.09a |

Mean + Standard deviation with different superscript letters in a row differ significantly (p < 0.05)

Lipid Composition

The results of the fatty composition of ice cream sample are presented in table 3 below. The fatty acids found in the ice creams are lauric acid (C12:0), myristi cacid (C14:0), plasmatic acid (C16:0), palmitoleic acid (C16:1), oleic acid (C18:1), linoleic acid (C18:2), linolenic acid (C18:3), arachidic acid (C20:0) and arachidonic acid (C20:1). In the ice creams of this study, lauric acid (C12:0) is the only medium chain fatty acids while myristic acid (C14:0), plasmatic acid (C16:0), palmitoleic acid (C16:1), oleic acid (C18:1), linoleic acid (C18:2), linolenic acid (C18:3), arachidic acid (C20:0) and arachidonic acid (C20:1) are the long chain fatty acids, present. The ice creams investigated had in them the range of fatty acids as: lauric acid (0.20 - 0.30)%, myristic acid (0.30 - 1.20)%, palmitic acid (18 - 25)%, palmitoleic acid (4 - 12)%, oleic acid (40 - 47)%, linoleic acid (10 - 18)%, linolenic acid (1.00 - 5.00)%, arachidic acid (1.00-2.00)% and arachidonic acid (0.50 - 2.00)%. The result revealed a significant different (P < 0.05) among the ice cream samples in the composition of all the fatty acids found except lauric acid. Medium chain fatty acids are easily digested, absorbed, transported via chylomicrons and metabolized by humans. Lauric acid, the only medium chain fatty acid found in the ice creams of this study according to Enig, 1998, can be broken down into monolaurin in human. Monolaurin is the active metabolite of lauric acid. It also appears that the incorporation of baobab fruit pulp had appreciably decreased the composition of saturated fatty acids (myristic, palmitic and arachidonic) and increased the unsaturated fatty acids (palmitic, oleic, linoleic, linolenic and arachidonic) of baobab fruit formulated ice cream. Cumulating evidence shows that saturated fat increases the risk of coronary heart diseases[17,18]. The predominant fatty acids (unsaturated fatty acids) including essential linolenic and linolenic fatty acids recorded in this study were significantly found higher in baobab fruit formulated ice cream. This indicates that inclusion of baobab fruit pulp had enriched the ice cream there by improved its health benefits. The percentages of the unsaturated fatty acids found in this study were also higher than those reported by Zofia et al, 2005.

Also presented in Table 3 below are the results of the percentage total fatty acids in plain and baobab fruit pulp incorporated ice creams. The plain ice cream has the total Saturated Fatty Acids (SFA) of 28.40% while the baobab fruit pulp incorporated ice creams had a total saturated fatty acids ranged from 18.30% to 24.80%. Monounsaturated Fatty Acid (MFA) of plain ice cream was 49.50% while those of baobab fruit pulp incorporated ice creams ranged from 52.00% to 56.00%. The polyunsaturated Fatty Acid of plain ice cream was 7.00% whereas, those of baobab fruit incorporated ice cream also ranged from 16.00% to 23.00%. There was no significant difference at P < 0.05 in total saturated and mono unsaturated fatty acids between plain and baobab formulated ice creams. However, baobab fruit formulated ice creams had significant higher sum total polyunsaturated fatty acid. The higher total polyunsaturated fatty acid reflecting higher percentage of essential linolenic acid (LA, C18:2n-6) and α-linolenic acid (ALA, C18:3n-3) in the ice creams was influence by baobab fruit incorporation. ALA has been shown to reduce the risk of heart attack, to reduce the growth of some tumours, and to lower blood pressure and blood triglyceride levels[19]. Many studies had shown that low LA intake is connected to high SFA intake, high cholesterol levels and high incidence of Coronary Heart Disease (CHD)[20].

The results in table 3 below also shows that the total cholesterol content of plain ice cream was 4.50mg/g while those of baobab fruit pulp incorporated ice creams ranged from 3.81 mg/g to 4.30 mg/g. There was significant decrease at P < 0.05 in the total cholesterol of the ice cream by the incorporation of baobab fruit pulp. The higher the levels of baobab fruit pulp the higher the reducing effect of total cholesterol in the ice cream. This might possibly translate into reducing hypercholesterolemia and cardiovascular risks associated with consumption of ice cream.

Mineral composition of ice cream

Table 2 presented the results of the mineral contents of plain (control) and baobab fruit incorporated ice creams. The macro-minerals investigated comprised of sodium, potassium, calcium, magnesium, iron and phosphorus while the micro-minerals studied are zinc, manganese, copper and selenium. The macro-mineral content of baobab incorporated ice cream were significantly (P < 0.05) higher than the plain ice cream. The macro minerals increased as the level of baobab fruit pulp incorporation increased. This was due to high mineral content inherent in baobab fruit pulp as reported by (Arnold et al., 1985). Incorporation of baobab fruit pulp does not negatively affect the macro-minerals of the ice cream but rather even improved it. The range of calcium (3.08 - 3.80) mg/100 g and phosphorus (3.06 - 3.50) mg/100 recorded in this study were lower than the values; calcium (11.20 - 58.39) mg/100 g and phosphorus (8.26 - 11.44) mg/100 g reported by Wiwat, 2008[21] on soy ice cream. However, the micro minerals (Zinc, Manganese and Selenium) of the baobab formulated ice creams were significantly (P < 0.05) higher than that of plain ice cream while there was no significant different in copper and manganese among the ice cream samples. Furthermore, the range of value for Iron (0.30 - 0.40) and Zinc (0.10 - 0.30) mg/100 g in this work conformed to those of Iron (0.29 - 0.51) mg/100 g and Zinc (0.18 - 0.33) mg/100 g reported by Wiwat, 2008[21] on soy ice cream.

Physicochemical properties

Table 4 shows the results of overrun, titratable acidity, total solid, melting point, milk solid not fat and water activity of the control and baobab fruit formulated ice creams. There were no significant differences at P < 0.05 between the plain and baobab formulated ice cream in total solid, melting point, water activity and milk solid not fat. However, the overrun and titratable acidity of the baobab formulated ice cream samples were significantly higher than that of plain ice cream. Increase in percentage overrun observed in baobab ice creams might resulted from the insignificant increase in their total solid. The range of percentage total solid in this study is closely related to the range reported by Umelo et al, 2014[22] on tiger nut ice cream.

The higher acidity in baobab incorporated ice creams might have been contributed by the organic acids including high vitamin c present in baobab fruit pulp. This could discourage the growth of proteolysis and lypolytic bacteria which are implicated for deterioration of ice cream that is not adequately freezed. The titratable acidity of the samples ranged from 0.19% to 0.22%. The results were within the level reported by Salamone[11] who said that the ice cream mix should have a normal acidity range of 0.19% to 0.22%. The result from the table also showed a slight increase in melting point of the ice cream as the inclusion level of baobab increases, indicating higher melting resistance[23-27].

Conclusion

Ice cream, a delicious food can be developed by replacing the cream with up to 20% of A. digitata pulp. This strategy has now provided for ice cream producers a new cost cutting means to slightly modify their existing recipes using baobab fruit pulp. They can produce a more nutritious and healthier ice cream with higher overrun and melting resistant while still keeping the physicochemical properties of the conventional ice cream. Interestingly, the inclusion of baobab fruit pulp had significantly reduced the total cholesterol and improved the polyunsaturated fatty acids composition of the ice cream.

Recommendations

This new strategy is recommended for home-made ice cream makers and industries to cut down the cost of procuring cream and avoid health problems associated with consumption of cream. Further studies should also be carried out to evaluate microbiological properties of the products.

References

1. El–Samahy, S.K., Youssef., K.M., Moussa-Ayoub T.E. Producing ice cream with concentrated cactus pear pulp: A preliminary study. (2009) J PACD 11: 1-12.

Pubmed l Crossref l Others

2. Manisha, P., Verma, R.K., Saraf, S.A. Nutraceuticals: new era of medicine and health. (2010) Asian J of Pharm Clin Res 3(1): 11-15.

Pubmed l Crossref l Others

3. Barminas, J.T., Charles, M., Emmanuel, D. Mineral composition of non-conventional leafy vegetables. (1998) Plant Foods for Hum Nutri 53(1): 29-36.

4. Bosch, C., Sie K. Asafa, B. Adansonia Digitata L. (Internet ) include protabase, Grubben, G.J.H and Denton, O.A (Editeurs) (2004) PROTA (plant Resource of Tropical Africa).

Pubmed l Crossref l Others

5. Abdalla, A.A., Nagla, E., Hussain, Y., et al. Production and Quality Evaluation of Baobab (Adansonia Digitata) Beverages. (2010) J App Sci Res 6(6): 729-741.

Pubmed l Crossref l Others

6. Namratha, V., Sahithi, P. Baobab: A Review about “The Tree of Life”. (2015) I J A Herbal Sci Tech 1(1): 20-26.

Pubmed l Crossref l Others

7. Aluko, A., Kinyuru, J., Chove, M.L., et al. Nutritional Quality and Functional Properties of Baobab (Adansonia digitata) pulp from Tanzania. (2016) J F Res 5(5): 23-31.

8. Compaoré, W.R., Nikièma, P.A., Bassolé, H.I.N., et al. Chemical Composition and Ant oxidative Properties of Seeds of Moringa oleifera and Pulps of Parkia biglobosa and Adansonia digitata Commonly used in Food Fortification in Burkin a Faso. (2011) Current Res J Bio Sci 3(1): 64-72.

Pubmed l Crossref l Others

9. Glew, R.H., Vanderjagt, D.J., Lockett, C.,. Amino acid, fatty Acid and Mineral composition of 24 Indigenous plants of investigations on the antiviral activities of medicinal plants of Togo. (1997) Pharmaceutical Biology 38: 46-50.

Pubmed l Crossref l Others

10. Sena, L.P., Vanderjagt, D.J., Rivera C., et al. Analysis of nutritional components of eight famine foods of the Republic of Niger. (1998) Plant Foods for Hum Nutr 52(1): 17-30.

11. Salamone, J.C. Polymeric material Encyclopedia. New York: CRC Press. (1998) J AM Chem Soc 120(27): 6848-6849.

12. Hack, B. Analytical method of determination of Mineral nutrients. In: Text on Analytical Practice. Dolphin and John (Eds). (2000). 1st Edn New York. 26-33.

Pubmed l Crossref l Others

13. Hesham, R. Lotfy., Celine, Mukakalisa., Celestine, Raidron. Analysis of different Namibian traditional oils against commercial sunflower and olive oils. (2015) A J Food Sci 9(6): 372-379.

14. Arnold, T.H., Wells, M.J., Wehmeyer, A.S. Khoisan food plants: taxa with potential for economic exploitation. In: Wickens, J.R., Goodin, and Field. D.V. London Ed plants for Arid Lands, Allen and Unwin, Pp. 69-86.

15. Specter, S.E. Sester, C.S. Sensory and physical properties of a reduced-calorie frozen dessert system made with milk fat and sucrose substitutes. (1994) J Dairy Sci 77(3): 708-717.

16. Hyvönen, l., Linna, m., Dijksterhuis, G., et al. Perception of melting and flavor release of ice cream containing different types and contents of fat. (2003) J Dairy Sci 86(4): 1130-1138.

17. Astrup, A., Dyerberg, J., Elwood, P., et al. Amino Acid, Fatty Acid and Mineral Composition of 24 Indigenous Plants of baobab seed (Adansonia digitata). (1997) Plant Foods for Human Nutrition 48: 113-117.

Pubmed l Crossref l Others

18. Baum, S.J., Kris-Etherton, P.M., Willett, W.C., Lichtenstein. Fatty acids in cardiovascular health and disease:a comprehensive update. (2012) J Clin Lipidol 6(3): 216-234.

19. Ruiz-Rodriguez, A., Reglero, G., Ibañez, E. Review – Recent trends in the advanced analysis of bioactive fatty acids. (2010) J Pharm Biomed Anal 5(2)1: 305-326.

20. Seppänen-Laakso, T., Laakso., Hiltunen, R. Analysis of fatty acids by gas chromatography, and its relevance to research on health and nutrition. (2002) A C A 465(1, 2): 39-62.

21. Wiwat W.C. Nutrition data and antioxidant capacity of soy milk ice cream and black sesame flavoured soy milk ice cream. (2008) As J Food Ag-Ind 1(4): 205-212.

Pubmed l Crossref l Others

22. Umelo, M.C., Uzoukwu, A.E., Odimegwu, E.N., et al. Proximate, Physicochemical and sensory evaluation of ice cream from blends of cow milk and Tigernut (Cyperus esculentus) milk. (2014) I J S R I T 1(4): 63-76.

Pubmed l Crossref l Others

23. Lily, M., Vargas- Rodriguze., Jesus, E., et al. AOAC (1990) Official Methods of Analysis. 15th Edition, Association of Official Analytical Chemist, Washington. DC. (2016) Food and Nutri Sci.

Pubmed l Crossref l Others

24. Arnold, T.H., Wells, M.J., Wehmeyer, A.S. Khoisan food plants: taxa with potential for economic exploitation. In: Wickens, J.R., Goodin, and Field. D.V. London Ed plants for Arid Lands (1985) Allen and Unwin 69-86.

25. Arbuckle, W.S. Ice cream, First ed. (1966) The AVI publ Co Inc West Port CT.

Pubmed l Crossref l Others

26. Felipe, Jochims., Celber C.P., Malcolm, J., et al. AOAC (1975) “Official Methods of Analysis” Association of Official and Analytical Chemists Washington DC. (2014) American J Plant Sci.

27. Besco, E., Bracioil, E., Vertuani, S., et al. The use of photo chemiluminescence for the measurement of the integral antioxidant Capacity of baobab products. (2007) Food and Chemi 102(4): 1352-1356.