Properties and Thermal degradation studies of Gelatin-based film –Exploring the biopolymer for plastic advancement

Asia Neelam1*, Omm-e-Hany1, Syed Junaid Mahmood2 and Shagufta Ishteyaq3

Affiliation

1 Institute of Environmental Studies, University of Karachi, 75270, Pakistan

2 Pakistan Council of Scientific and Industrial Research (PCSIR), Karachi, Pakistan

3 Department of Chemical Technologies, University of Karachi, 75270, Pakistan

Corresponding Author

Asia Neelam, Institute of Environmental Studies, University of Karachi, 75270, Pakistan, E-mail: neelamsaleem131@yahoo.com

Citation

Neelam, A., et al. Properties and Thermal Degradation Studies of Gelatin-Based Film –Exploring the Biopolymer for Plastic Advancement (2018) Int J Food Nutr Sci 5(1): 69- 73.

Copy rights

© 2018 Neelam, A. This is an Open access article distributed under the terms of Creative Commons Attribution 4.0 International License.

Keywords

Polymer; Gelatin; Tensile strength; Thermo gravimetric analysis

Abstract

Gelatin is an important natural biopolymer protein extracted from fibrous insoluble collagen and broadly used by various industries because of its stabilizing, and easy handling usage. Nowadays, scientists are interested to find out the alternative polymer of plastic, provide food safety as well having the properties of rapid degradation and environmental friendly. In this study, an investigation was carried out to figure out the property of gelatin as a bioplastic polymer. Gelatin based Biofilms are produce in laboratory by solution casting method in Petri plates. The prepared biofilms characterized by Tensile strength, Break point elongation, swelling behavior, thermo gravimetric analysis and degradation. Food coating test were also employed to analysis the gelatin coating protection on food materials.

Introduction

There is an alarming situation of environment because of petro-based plastic which enormously effect our planet because of its persist, xenobiotic nature, disposal and production of toxic dioxin, vinyl, and polystyrene during the incineration of plastic wastes[1-3]. Along with these problem CO2 emission from plastic manufacturing industries were expediently increase from 1971 - 2004, which contributing in the global warming[4]. Approximately 6% of the whole oil supply of the world is used in the production of plastics and its packing products[5]. Plastic utensils releases carcinogenic or hormonal disruption chemicals (bisphenol-A) upon heating and mixed with food (Mcrandle, 2004). Low Density Polyethylene (LDPE) is contribute as a major cause of environmental pollution due to its recalcitrant nature and characterized as a non-biodegradable thermoplastic until they fragmented into low molecular weight that can easily assimilated by microorganism[6]. Sometime their figments produce toxic monomer that links to the cancer and reproductive problems, hence interest is rapid demand to develop the material which don’t burden the environment.

Now people are more aware about the harmful effects of petrochemical derived plastic materials in the environment now they are switching towards the ecofriendly solution which can be disposed in environment and can easily degrade through the enzymatic actions of microorganisms follow a full equation of mineralization i.e water, CO2 biomass, humic matter and various other natural[7]. This is also called as a genuine biodegradable plastic, due to the absence of any toxic by product.

Today, The development of biodegradable food packaging has been a subject of interest over the years[8,9]. Bioplastic is not as new as we know, in the late 80s scientist of Massachusetts Institute of Technology isolate the novel enzyme ‘thiolase’ which performs the key role in the biological production of bioplastic followed by the discovery of the genes required for the synthesis than in the 1987 first patent application of bioplastic were made which is accepted in 1993[10]. Along many natural sources of bioplastic, Gelatin has many application benefits on film manufacturing including good film-forming, well gas and oil resistance, low price, nontoxicity, and ultimately biodegradable properties. It is a promising candidate in the bioplastic manufacturing field for food and drug packaging[11].

Materials and Methods

Preparation of film: In the preparation of film Gelatin powder were purchased from supplier (Merk) and glycerin 99% purity (food grade), 12 grams of gelatin powder dissolved in 80 ml of hot water, fortified with 3 ml of glycerin as plasticizer. Heat the mixture till it becomes clear and thick. Stirr spatula continuously to avoid lumps in the solution. After 15 mints pour the mixture into the Petri plates and let it dry for 24 Hours.

Mechanical testing: Mechanical properties of prepared Biofilm including tensile strength and elongation at breakpoints were analyzed at room temperature as per ASTM D412 standard using universal testing machine (Model Instron-4301) at cross head separation rate 10 mm/min. Recorded values of tensile strength and elongation is the average of three measurements.

Swelling Index: The water sorption capacity of film investigated by Gravimetric method, at room temperature (23 ± 2 °C) pre-weighted sample of biofilm was soaked with deionized water for required time, drawn the sample and dried on filter paper and then reweight. The swelling percentage was calculated using the formula (Ali et al., 2017).

Where Wα is a weight of sample after soaking and WΩ represents the initial weight of sample respectively, this method was adapted from[12].

Biodegradation test: The biodegradation behavior of gelatin carried out by ascertains the loss in weight during the soil burial test. Garden soil and coastal area (1200 g) soil was taken in different pots. A weighed amount (1 g) of each of the samples that is, Gelatin and LDPE (as control) was buried in the pots such that the soil covered the polymer from all the sides. The pots were kept at ambient condition and amended with mineral salt media. The film was taken out from the soil, washed and dries to check for any weight loss.

Weight loss measurement: The films after soil burial test were analyzed by gravimetrically through weight loss calculation.

Where Wi the initial weight of the film sample and Wf is the treated weight of the film after exposed to the soil.

UV barrier property: UV barrier properties of gelatin biofilm were testing using the simple protocol. A pre culture Bacillus subtilis petriplate (9 cm in diameter) were half covered with gelatin film were exposed to UV light ( 252 nm) for 15 mins and 25 mins, than petri plates were incubated at 35 °C for 24 hours. Tests were performed in triples.

Fruit Coating: Apple fruits (Malus domestica var. Anna) were purchased from local market of Karachi, Pakistan. Fruit sample were sorted for equal size and without defect. Then, they were washed with 20% Acetic acid to remove commercial coating and sanitized by 250 ppm sodium hypochlorite solution for 2 min. Samples were washed thoroughly with distilled water, air dried and then coated with Gelatin solution. Experiment were done in replicates and store in ambient condition. Moisture content of samples was monitored periodically according to the design protocol. All the experiment was repeated thrice and standard deviation were calibrated.

Thermo Gravimetric Procedure: Thermo Gravimetric Analysis (TGA) was performed using TA instrument (TGA/ SDTA 851 MettlerTelodo). TGA analyzer was used to measure and record the sample mass change with temperature during the thermal degradation reaction. During this study TGA providing with gas controller (TS0800) with nitrogen gas purging rate would 65 ml /min throughout experiment. The temperature rate was set around 300 -800K with the temperature increasing rate 30 °C/ min.

Theoretical consideration: The most common differential is conversional method is that of Friedman. It is the most straightforward way to evaluate the effective activation energy (Ea). This method is a differential is conversional method, and it directly based on following equations

Where A, R and E is the pre-exponential factor, gas contact and activation energy successfully drive by the Arrhenius equation, given by

From the logarithm of equation (a) it is easy to obtain values for E over a wide range of conversions by plotting β dx/dT against 1/T for a constant x value.

K (T) the temperature dependence of the rate of weight loss (x). Wo is the initial weight (mg), wt weight after time “t” minutes and WΩ is the weight after pyrolysis (mg) (Aboulkas et al 2010, Friedman 1964).

Another way to calculate the activation energy is by using weight loss data for analysis of decomposition of kinetics of Gelatin. The extent of conversion of material pyrolyzed ‘x’ were define by equation 1. Than the rate of reaction can also be written as

Where R is the universal gas constant, E is the activation energy and k0 is the pre exponential factor. The integration of Equation (2) result an Activation energy, which can easily be calculated by plotting a graph of ln [-ln(1-x)] against 1/T ( Kayacan and Dogan 2008).

Results and Discussion

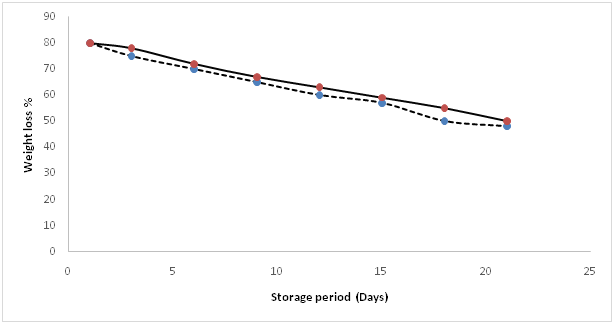

The aim of this work was to evaluate the effectiveness to Gelatin as a biopolymer for synthesis of plastic. Biopolymers are widely used as packing materials because of their good degradability as they are typically extracted from natural origin. They can easily characterized as edible coating as they applied directly to the food surface by dipping, coating or spraying[13]. Gelatin, typically characterized as protein were coating on apply to enhance the shelf life, the freshness of apple remain up to 22 days during the study period at ambient condition. After 22 days of storage in ambient condition weight loss of apple (Malus domestica var. Anna) were found to be steadily decrease in control as compared to coated apples (Figure 1) as the coated gelatin layer delayed the migration of moisture in the environment. Similarly waxes are also used as food coating to increase the shelf life but their mixing with artificial additives like thiabendazole is most harmful effect, reported to cause bladder cancer. However, Chitosan and Cellulose as a natural polymer for coating of fruits, bring environmentally safe and good film forming characters[14-17]. Inconstant to these natural polymers, gelatin is protein whereas chitosan and wax are polysaccharides and lipid respectively. According to[18] protein based films possess better properties than polysaccharide films. This protein based Gelatin film also incorporated with essential oil to increase its antimicrobial and antioxidant potential[19]; prepared a gelatin film with essential oil of lemon grass to extend is properties and self-life during store period i.e. refrigeration.

Figure 1: Effect of Gelatin coating solution and uncoated on weight loss of Apple fruit at ambient condition.

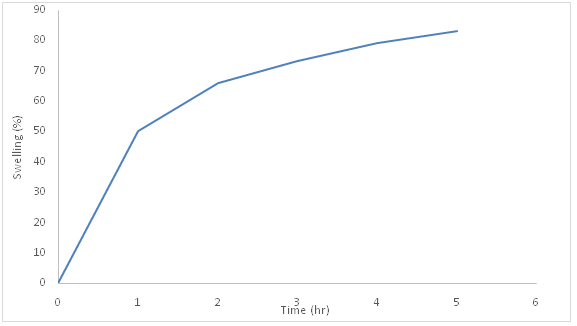

Figure 2: Graphical representation of swelling property of gelatin film.

The visible change was found in the degradation of gelatin film by soil burial test (Table 1). In Garden soil 80% degradation rate were calculated in 5 days whereas in Coastal soil 70% estimated. The days rate of degradation is approximate calculated as 16% and 14% respectively. However in the same experimental condition no weight loss was observed in LDPE samples during 5 days. In contrast to the petroleum based plastic, bioplastic can be easily biodegradable with no environmental damage. In assessment of soil burial test the surface of plastic or bioplastic acts as a carbon and nitrogen source for microorganism growth, therefore microorganism consume it as food and increase their biomass. However microbial development depends on the constitute and the nature of polymer[20]. Our result indicates no net change in LDPE weight as it contain long carbon chain which is hydrophobic in nature makes them microbial resistant. It is estimated that under normal condition polymer takes more than 10 decades for its complete mineralization[21-23]. According to Roy et al., (2007) polyethylene degrade 0.5% in 100 years and with exposed to sunlight for 2 years its degradation is around 1%. According to the Maheshwari et al., 2013) Biodegradable plastic have many advantages as it has non-toxic end product, much safer for consumer point of view, consume less than 65% energy than production of conventional plastic. However there is lot of room for improvement is present in Bioplastic.

Table 1: Weight loss of plastic after 5 days of study period with comparison of Garden and Coastal soil.

| Samples | Garden Soil | Coastal soil |

|---|---|---|

| Gelatin film | 0.2 g | 0.3 |

| LDPE | 1 g | 1 g |

For the approach of swelling behavior of films were emerged in water to verify the effect and analysis the hydrophilic nature of gelatin based films. Water diffuses into the network chains of the films, thus causing the film to swell. The swelling of the films were rapid during the initial hours and later followed by slower swelling rate until the film was fragmented into smaller pieces. Wang et al., (2008) gelatin material tends to swell or dissolve in high moisture content due to its high hydroscopic nature. Therefore composite film will be recommended with combination to polysaccharide and other natural and synthesis material for film manufacturing.

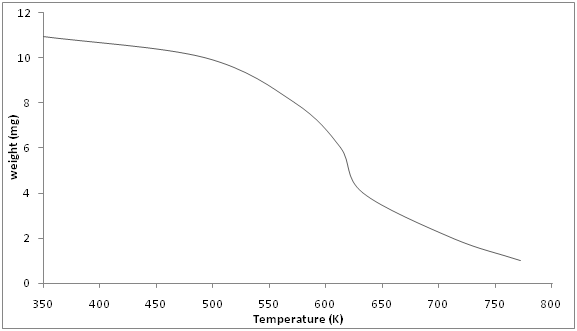

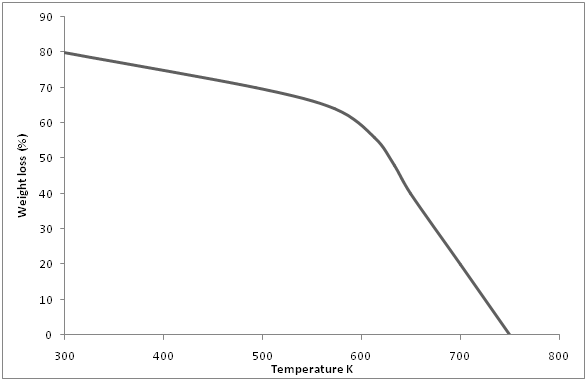

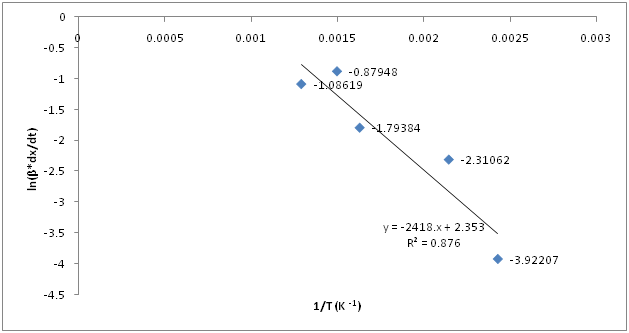

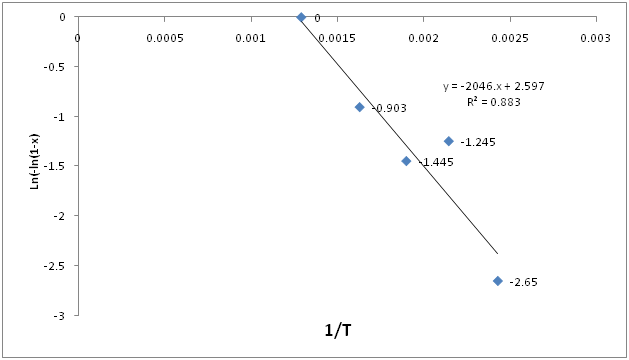

Thermo Gravimetric Analysis (TGA) of the experimental sample is based on weight vs. temperature. This techniques mostly used for kinetic analysis of devolatilization process, shows the behaviors of polymer. They show server changes upon heating and release gases and liquids with a change in their shape, color and molecular weight[24]. Here the mass of the polymer is measure as function of temperature and time. At ambient and 300 °C mostly moisture, residual solvent, additives and oligomers generally evaporate amino resins. Volatile degradation products generally required temperature above 200 °C. When the Gelatin plastic began to decompose at high temperatures, the thermo gram show a drop in the curve indicating a loss of mass at high temperature. The degradation temperature of gelatin is around 340 °C. The weight of the sample decreases as the temperature of TGA increase (figure 3). Initially at low temperature T ( < 150 °C) compounds having low molecular weight like water decomposed first, temperature between (150 - 250 °C) additives decomposed. At the temperature of 250 - 500 or more thermal (inert gas) or thermo oxidative decomposition occur. The pyrolysis of gelatin by thermogravimetry revealed the decomposition in three stages: water evaporation, active and passive pyrolysis and the decomposition. As we can see from figure 3, the devolatization occurs at about 450 K and the process continuously increase with the loss of weight until the temperature reaches about 750 K. The apparent value of activation energy is about 20 KJ/mol from the Friedman method Figure 5 and the method of integral present by (Kayancan and Dogan 2008) gives approximately 17 KJ/mol activation energy Figure 6. Both the methods shows reasonable fitting of data to the straight line provide around same amount of activation energy at the same heating rate.

Figure 3: TGA curve of gelatin shows the relationship of weight and temperature.

Figure 4: Mass loss versus temperature curve of TGA at heating rate 5 K/min.

Figure 5: ln(β*dx / dt) as a function of 1/T for the pyrolysis reaction of Gelatin film by friedman method

Figure 6: Ln(-ln(1-x) as a function of 1/T for the pyrolysis reaction of Gelatin film.

Table 2: Comparison of Ultraviolent radiation on gelation and plastic film on different exposure time.

| Samples | Exposure Time (5 minutes) | Exposure Time (15 minutes) | Exposure Time (25 minutes) |

|---|---|---|---|

| Gelatin film | +++ | +++ | +++ |

| LDPE | --- | --- | +-- |

| Control | --- | --- | --- |

Table 3: Physical process of gelatin film with comparison of LDPE

| Type | Tensile strength (Mpa) | % Elongation | Thickness (mm) |

|---|---|---|---|

| LDPE | 20.5 ± 0.56 | 611 ± 0.56 | 0.15 |

| Gelatin | 6.38 ± 0.20 | 171 ± 4.8 | 0.163 |

Conclusion

In conclusion, this study showed that gelatin can be utilized as a promising biopolymer in the plastic advancement. As solo compound it is very week in tensile strength and bearing a property of hydrophilic nature but having a high ability of degradation make it applicable in synthesis of plastic but for the point of strength it is recommended to use it by mixing a certain amount of synthesis and gelatin polymer, so it may meet all the performance requirement on packing industries. As the Biopolymer industries have a positive future all the sectors now required biodegradable and environmentally friendly polymer due to its environmental benefits.

References

- 1. Han, J., Shin, S. H., Park, K. M., et al. Characterization of physical, mechanical, and antioxidant properties of soy protein based bioplastic films containing carboxymethylcellulose and catechin. (2015) Food Sci Biotech 24(3): 939-945.

Pubmed|| Crossref || Others

- 2. David, K. A. B., Francois, G., Richard, C. T., et al. .Accumulation and fragmentation of plastic debris in global environments. (2009) Phil Trans R Soc 364: 1985-1998.

Pubmed|| Crossref || Others

- 3. Álvarez-Barragán, J., Domínguez-Malfavón, L., Vargas-Suárez, M., et al. Biodegradative activities of selected environmental fungi on a polyester polyurethane varnish and polyether polyurethane foams. (2016) Appl Environ Microbio 82(17): 5225-5235.

- 4. Nordell, B. Thermal Pollution Causes Global Warming. (2003) Glo Plane Cha 38: 305-312.

- 5. Zawya. Global plastic production grew over 500percent over the last 30 years. (2010).

Pubmed|| Crossref || Others

- 6. Francis, V., Raghul, S.S., Sarita, G.B., et al. Microbial degradation studies on linear low-density poly(ethylene)-poly (vinyl alcohol) blends using Vibrio sp. (2010) Int Conf adv poly Tec 26-27

Pubmed|| Crossref || Others

- 7. Azios, T. A primer on biodegradable plastics. (2007) Chr Sci Moni.

Pubmed|| Crossref || Others

- 8. Shah, A. A., Hasan, F., Hameed, A., et al. Biological degradation of plastics: a comprehensive review. (2008) Bio Adv 26(3): 246-265.

- 9. Iwata, T. Biodegradable and bio-based polymers: future prospects of eco-friendly. (2015) Angew Chem Int Ed Engl 54(11): 3210-3215.

- 10. DiGregorio, B.E. Biobased Performance Bioplastic: Mirel. (2009) Chem Bio 16(1): 1-2.

- 11. Patil, R. D., Mark, J. E., Apostolov, A., et al. Crystallization of water in some crosslinked gelatins. (2000) Euro Poly J 36(5): 1055-1061.

- 12. González, A., Alvarez Igarzabal, C. Soy protein–Poly (lactic acid) bilayer films as biodegradable material for active food packaging. (2013) Food Hyd 33(2): 289-296.

- 13. Yang, G., Yue, J., Gong, X., et al. Blueberry leaf extracts incorporated chitosan coatings for preserving postharvest quality of fresh blueberries. (2014) Postharvest Bio Tech 92: 46-53.

- 14. List, D. Reregistration eligibility decision for thidiazuron. (2005) Environ Prot 4: 1-12.

Pubmed|| Crossref || Others

- 15. Khalifa, I., Barakat, H., El-Mansy, H.A., et al. Enhancing the keeping quality of fresh strawberry using chitosanincorporated olive processing wastes. (2016) Food Biosci 13: 69-75.

- 16. Shao, X.F., Tu, K., Tu, S., et al. A combination of heat treatment and chitosan coating delays ripening and reduces decay in ‘‘GALA” apple fruit. (2012) J Food Qual 35(2): 83-92.

- 17. Martı´nez-Camacho, A.P., Cortez-Rocha, M.O., Ezquerra-Brauer, J.M., et al. Chitosan composite films: thermal, structural, mechanical and antifungal properties. (2010) Carbohydr Polym 82(2): 305-315.

- 18. Cuq, B., Gontrad, N., Stéphane, G. Proteins as Agricultural Polymers for Packaging Production. (1998) Guilbert Ceral chem. 75 (1): 1-9.

- 19. Ahmed, M.S., Benjakul, P.S., Nirmal, N.P. (2012) Int.J.food Microbiology 155: 171-178.

Pubmed|| Crossref || Others

- 20. Nathalie, L., Christophe, B., Christian, B., et al. Polymer biodegradation: Mechanisms and estimation techniques. (2008) Chemosphere 73(4): 429-442.

- 21. Gajendiran, A., Sharmila, K., Abraham, J. Microbial degradation of low-density polyethylene (LDPE) by Aspergillus clavatus strain JASK1 isolated from landfill soil. (2016) Biotech 6(1): 52.

- 22. Ohtake, Y., Kobayashi, T., Asabe, H., et al. Studies on biodegradation of LDPE—observation of LDPE films scattered in agricultural fields or in garden soil. (1998) Polym Degrad Stab 60(1): 79-84.

- 23. Contat-Rodrigo, L., RibesGreus, A. Biodegradation studies on LDPE filled with biodegradable additives: morphological changes. (2001) J Appl Polym Sci 83(8).

- 24. Mohammed, A. A., Plastics Chemistry. (1993) University of Mosul, Iraq.

Pubmed|| Crossref|| Others